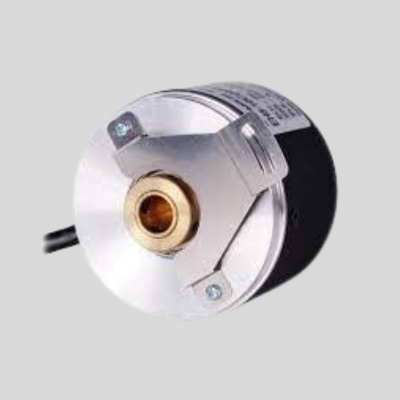

DELTA ENCODERS IN INDIA

Industrial Direct India is a leading dealer and distributor of Delta Encoders in India. We distribute Delta Encoders in Chennai, Bangalore, Pune, Mumbai, Ahmedabad, Hyderabad and Delhi.

Delta Encoders have become a trusted name in the field of motion control, providing high-performance solutions for various industrial and automation applications.

Delta Electronics offers a comprehensive range of encoders in India, catering to both incremental and absolute feedback needs. These encoders are engineered to ensure high accuracy and reliability in demanding industrial environments, making them a go-to choice for businesses seeking efficient automation solutions.

Delta Encoders are advanced motion sensing devices designed to provide accurate and reliable feedback for position, speed, and direction control in a wide range of industrial applications. As a key part of Delta Electronics’ automation solutions, these encoders are engineered to meet the high standards required for modern industrial systems, ensuring seamless integration, precision, and long-lasting performance.

Applications of Delta Encoders

Delta Encoders are extensively used across various sectors due to their versatility and efficiency.

Robotics and Automation

Delta encoders provide crucial feedback for precise motion control in robotic arms, assembly lines, and automated systems.

CNC Machining

Delta encoders provide accurate position feedback to ensure the precision required for milling, drilling, turning, and other machining operations.

Textile Industry

Delta encoders are used in textile machines such as looms, spinning machines, and knitting machines, ensuring consistent control

Energy and Power

In power generation plants, wind turbines, and energy distribution systems, Delta encoders are used for monitoring and controlling the rotation of machinery.

Material Handling Systems

Delta encoders are used in conveyors, AGVs, and sorting systems to ensure the accurate movement of materials.

Key Features of Delta Encoders

Long Operational Life

Built with quality materials and components, Delta encoders are designed for long-term durability, reducing the need for frequent maintenance or replacement.

Compact Design

Delta encoders are compact and lightweight, making them easy to integrate into various systems and minimizing space requirements.

IP65 Rating

These encoders come with IP65 protection, ensuring they are resistant to dust and water, making them ideal for challenging industrial environments.

Flexible Output Options

Available with various output configurations such as open collector, push-pull, and differential line driver, allowing easy integration with different control systems.

High Resolution

Delta encoders provide high-resolution feedback, allowing for precise motion control and improved system performance.

DELTA ENCODERS – ETA Series

The ETA Series from Delta Encoders offers high-precision motion feedback solutions for a wide range of industrial automation applications. Designed for demanding environments, the ETA Series is renowned for its robustness, accuracy, and reliability.

Delta’s ETA Series encoders provide a comprehensive range of features that cater to the diverse needs of industrial motion control systems, ensuring optimized performance and minimized downtime.

Applications of DELTA ENCODERS – ETA Series

Printing Industry

Elevator and Lift Systems

Packaging Machines

CNC Machines

Robotics

Specification

Industry Compliance : Compliant with global standards for electromagnetic compatibility (EMC) and environmental protection.

Lifespan and Durability : Long operational life with robust construction designed to withstand vibrations and harsh conditions.

Mechanical Dimensions : Compact and lightweight design for ease of installation and space efficiency.

Shaft Options : Available with solid and hollow shaft configurations for easy installation.

Operating Temperature : Operates in a wide temperature range from -20°C to +85°C, ensuring reliability in varied environments.

Speed Range : Capable of handling speeds up to 12,000 RPM, suitable for high-speed operations.

Operating Voltage :5V to 24V DC, allowing compatibility with different industrial systems.

Protection Rating : IP65 rated, offering protection against dust and water, ideal for harsh industrial environments.

Output Types : Available with various output configurations: differential line driver, push-pull, and open collector.

DELTA ENCODERS – AS5 Series

Delta AS5 Series Encoders are high-performance devices designed to provide precise feedback for position, speed, and direction in industrial automation systems.

Application of DELTA ENCODERS – AS5 Series

Printing Industry

CNC Machines

Robotics

Textile Industry

Elevator and Lift Systems

Packaging Machines

Specification

Lifespan and Durability : Long operational life with robust construction that minimizes maintenance and downtime.

Mechanical Dimensions : Compact and lightweight design, facilitating easy installation and space efficiency.

Shaft Options : Available with solid and hollow shaft configurations for flexible installation.

Operating Temperature ; Wide operating temperature range from -20°C to +85°C, ensuring reliable performance in diverse conditions.

Speed Range : Capable of handling speeds up to 12,000 RPM, suitable for high-speed applications.

Operating Voltage : 5V to 24V DC, offering wide compatibility with different industrial control systems.

Output Types : Available with various output configurations: push-pull, differential line driver, and open collector.

Protection Rating : IP65 rated, providing protection against dust, water, and harsh environments.

DELTA ENCODERS – CS7 Series

The Delta CS7 Series Encoders are designed to provide high-performance motion feedback in industrial automation systems that require precision, reliability, and versatility. These encoders are engineered to support a wide range of applications, from high-speed machinery to complex automated systems, ensuring consistent performance across diverse environments.

The Delta CS7 Series encoders deliver accurate position and speed feedback, enabling precise control of machinery and equipment

Applications of DELTA ENCODERS – CS7 Series

Robotics

CNC Machines

Elevator and Lift Systems

Printing Industry

Packaging Machinery

Textile Industry

Specification

Lifespan and Durability Long operational life with robust construction, reducing maintenance needs and downtime.

Mechanical Dimensions Compact design for easy installation in tight spaces with lightweight construction.

Shaft Options Available with solid and hollow shaft configurations for flexible installation.

Operating Temperature Wide operating temperature range from -20°C to +85°C, ensuring reliability in various environments.

Speed Range Can handle speeds up to 12,000 RPM, making it suitable for high-speed applications.

Operating Voltage 5V to 24V DC, providing compatibility with a wide range of control systems.

Protection Rating IP65 rated, offering protection against dust, water, and harsh environments.

Output Types Available with push-pull, differential line driver, and open collector output configurations.

Resolution : Up to 5,000 pulses per revolution (PPR) for precise motion feedback.

Why Choose Delta Encoders

Durability and Reliability

Delta Encoders are built to withstand the most demanding environments. Featuring durable housing, they offer protection against dust, moisture, and vibrations, making them ideal for industries where harsh conditions are common.

Wide Range of Applications

Delta encoders are used in a variety of industrial sectors, including:

- Automation Systems: For controlling motors, actuators, and other devices in automated production lines.

- Robotics: Essential for providing feedback for accurate positioning and movement of robotic arms and automated systems.

- CNC Machines: Used to maintain precise control of machine tools for milling, drilling, and turning.

High Precision and Accuracy

Delta Encoders are designed to provide precise position, speed, and direction feedback, making them ideal for applications where accuracy is critical.

FAQ

How do Delta Encoders communicate with control systems?

Delta Encoders typically communicate through digital signals, outputting pulses that are interpreted by controllers or PLCs to calculate position, speed, or direction. The output can be configured in several ways, including open collector, push-pull, or differential line driver, depending on the system’s requirements.

How do I select the right Delta Encoder for my application?

To select the right encoder for your needs, consider the following factors:

- Resolution: Higher resolutions are needed for more precise control.

- Speed: Ensure the encoder can handle the required RPM.

- Shaft Configuration: Choose between solid or hollow shaft based on installation requirements.

- Output Type: Ensure compatibility with your control system (push-pull, differential line driver, etc.).

- Environmental Conditions: Consider IP rating, temperature range, and protection needs based on your application.