Automation OEM Machine Manufacturers

Automation for OEM machine manufacturers involves incorporating advanced technologies like robotics, IoT, AI, and programmable control systems into the design, production, and operation of machinery. These technologies optimize processes, improve machine performance, and enable smarter, more efficient equipment.

Industrial Direct India are the masters of world firsts, engineering the first Digital DC drive in 1986, the first Flux Vector Drive in 1989 followed by the first universal AC/Servo Drive in 1996. Since then we have continued to grow and innovate from drives designed to fit the smallest spaces resulting in overall machine footprint reduction to the new multi-protocol solution.

Original Equipment Manufacturers (OEMs) provide standard solutions to a particular manufacturing requirement, such as packaging machines, material handling systems or air handling units.

Key Technologies in OEM Machine Automation

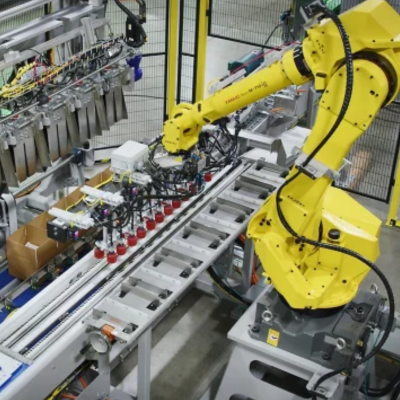

Robotics

Robots streamline complex tasks like assembly, welding, and material handling, improving efficiency and precision.

IoT and Sensors

IoT-enabled devices provide real-time data on machine performance, allowing for proactive adjustments and maintenance.

PLC (Programmable Logic Controllers)

PLCs provide precise control over machine functions, ensuring seamless integration and operation.

HMI (Human-Machine Interface)

HMIs offer intuitive control and monitoring of machinery, enhancing user experience and productivity.

Applications of Automation in OEM Machine Manufacturing

Machine Monitoring

Real-time data tracking for operational insights and predictive maintenance.

Assembly Lines

Automating assembly processes to increase efficiency and reduce manual errors.

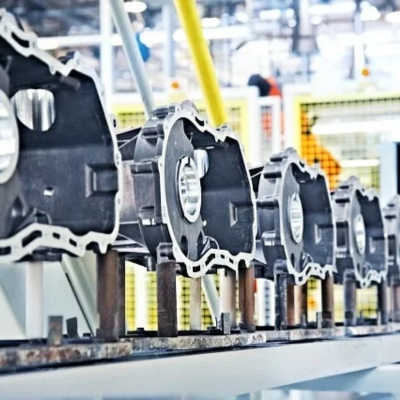

Component Manufacturing

Using robotics and precision tools for consistent component quality.

Machinery Design and Development

Enhancing design accuracy and testing through simulation and prototyping tools.

CNC Machining

Computer Numerical Control (CNC) machines automate the machining process, allowing for high-precision cutting, drilling, and shaping of materials.

Benefits of Automation for OEM Machine Manufacturers

Scalability

Automation systems are scalable, making it easy for OEMs to adapt to growing production demands and market changes.

Customizable Solutions

Advanced technologies enable OEMs to design machines tailored to specific customer needs, enhancing market competitiveness.

Cost Savings

By optimizing resource usage, reducing waste, and minimizing manual labor, automation significantly lowers operational costs.

Improved Precision

Automated systems ensure high accuracy in machine components and assembly, leading to reliable and efficient equipment.

Enhanced Productivity

Automation speeds up production cycles and reduces downtime, allowing OEMs to meet tight deadlines without compromising quality.

FAQ

How does automation reduce costs for OEM manufacturers?

Automation reduces costs by minimizing waste, optimizing resource usage, and reducing the need for manual labor. Predictive maintenance and process optimization also lead to fewer breakdowns and less downtime, contributing to significant savings.

How does automation improve the precision of OEM machines?

Automation ensures high precision by eliminating human errors and performing tasks with consistent accuracy. Robotics, smart sensors, and AI-powered systems can achieve complex tolerances and precise assembly, ensuring that OEM machines meet quality standards and perform reliably.