SIEMENS GEAR MOTOR IN INDIA

We distribute Siemens gear motor in Chennai, Bangalore, Pune, Mumbai, Ahmedabad, Hyderabad and Delhi.

Siemens offers a complete range of geared motors in all gear unit types with a wealth of product advantage as part of the most comprehensive, integrated drive and automation concept worldwide. SIMOGEAR supports known and established design routines, allowing you to freely select suppliers and completely modernize or reconfigure your complete drive solutions at any time – with low associated costs.

Applications of Siemens Gear Motor

Siemens gear motor are used in a variety of applications across multiple industries:

Pump and fan Systems

Suitable for driving pumps in water treatment plants, sewage systems, and irrigation systems.

Used in HVAC systems, cooling towers, and ventilation systems to ensure efficient airflow.

Conveyor Systems

Ideal for powering conveyor belts in warehouses, distribution centers, and packaging industries.

Industrial Automation

- Used in manufacturing plants, assembly lines, and production facilities for precise and reliable motion control.

- Automated conveyors, hoists, and lifting equipment.

Specialized Machinery

Employed in various specialized machinery and equipment across different industries.

Key Features of Siemens Gear Motor

Customization

Siemens offers customized solutions to meet specific customer requirements, ensuring optimal performance and compatibility.

Compact Design

The compact and lightweight design makes installation and integration into existing systems easy and straightforward.

Versatility

Suitable for a wide range of applications, including conveyors, pumps, fans, and other industrial machinery.

Durability

Built with high-quality materials, these motors are designed to withstand harsh industrial environments and ensure long-term reliability.

High Efficiency

Siemens gear motors are engineered for high efficiency, ensuring optimal performance and energy savings.

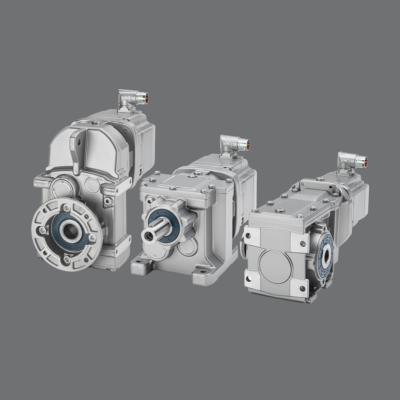

SIEMENS GEAR MOTOR – SIMOGEAR GEAR MOTORS

SIEMENS is offering the compact and versatile geared motor solutions that can be optimally integrated into the drive train. Always both precise and powerful. More flexibility, more power, a more standard approach – these are the expectations of the sector, especially in conveyor technology.

SIMOGEAR gear motor delivers performance from 0.09 kW up to 55 kW. It can achieve a gear unit torque up to 19.500 Nm with helical, parallel shaft, helical bevel and worm geared gear units, additional types and sizes. Due to accordance to the current measures, SIMOGEAR is compatible to many other suppliers of geared motors. The new series of SIMOGEAR geared motors is 1:1 compatible to the general standard in the market, and can therefore be simply integrated into existing or new machines and systems.

Applications of SIEMENS GEAR MOTOR – SIMOGEAR GEAR MOTORS

Agricultural

Material Handling

Packaging

Textile Industry

Mining and Cemen

Food and Beverage

Pumps and Fan

Features

Packaged goods transport

Rope lifter

Storage & retrieval systems (ASRS)

Carriage drives

Travel drives and hoists

Automatic guided vehicles (AGVs)

Conveyors – all kinds

Quicker

- Faster to design and order

Easy-to-use online configuration tool provides exact 3D CAD data and a detailed summary of your configured gear motors - Reduced installation time

Lightweight aluminum housings make units easier to handle, and the SIMOLOC keyless tapered hollow shaft locking system allows for ease of installation

SIEMENS GEAR MOTOR – HELICAL WORM GEAR MOTORS

Helical worm geared motors are offered in 2 stage version. The mounting offering includes solid and hollow shafts. They are energy efficient and usually chosen when demand for drives with angular geared motors. Due to worm gear stage, high ratios can be implemented. SIMOGEAR helical worm geared motors represent the cost-effective solution for angular geared motors in the lower torque range. They achieve extremely low noise and are used by example in waste water system and as drives in theaters.

Application of SIEMENS GEAR MOTOR – HELICAL WORM GEAR MOTORS

Stage technology

Presses

Car wash plants

Specification

Solid shaft, hollow shaft, hollow shaft with splined shaft, hollow shaft with shrink disk, and SIMOLOC keyless tapered shaft locking system

Foot, flange mounting

2-stage construction

NEMA Premium® motors

Energy efficient (Mechanical efficiencies up to 96%)

Integrates with Siemens drives and automation

SIEMENS GEAR MOTOR – SERVO GEAR MOTOR

Geared motors to address a wide range of applications. Geared motors are extremely versatile, which is reflected in the fact that we offer a wide range of geared motor variants. Servomotors equipped with high precision and economical planetary gearboxes are available to address a wide range of applications.

Application of SIEMENS GEAR MOTOR – SERVO GEAR MOTOR

Industrial Automation

Conveyor Systems

Specialized Machinery

Pump and Fan Systems

Features

SIMOTICS S-1FG1 servo geared motors use the same operating heads as SIMOGEAR geared motors.

The range of types includes helical, parallel shaft, bevel and helical worm geared motors in the usual frame sizes and speed/torque classes.

The SIMOTICS S-1FG1 servo gear motors have smaller dimensions, weigh less and have a higher dynamic response than standard induction geared motors.

Prefabricated MOTION-CONNECT signal and power cables mean that the components can be simply and perfectly connected with one another.

The system can be quickly commissioned as a result of the electronic type plate and the fact that the motors are connected via the DRIVE-CLiQ system interface.

Motors, drives and commissioning tools are optimally coordinated and harmonized with one another.

SIEMENS GEAR MOTOR – HELICAL BEVEL GEAR MOTORS

Helical bevel are angular geared motors where the gear unit output shaft is rotated 90° to the motor shaft. Units can either have a solid or a hollow shaft. Helical bevel geared motors represent the ideal solution for drive tasks where an angular geared motor with high power density is required with continuously high output torques SIMOGEAR helical bevel geared motors can reach high gear ratios and they are highly energy efficient (efficiencies 98% per stage).

They are also able to achieve high gear ratios and have high power density. They can be used in narrow constructions – places with delimited spatial conditions. Offered in stages 2 and 3 in foot or flange-mounting version with solid or hollow shafts, SIMOGEAR helical geared motors are used for baggage and material handling conveyors, rope lifts in warehouse logistics and for carriage drives.

Applications of SIEMENS GEAR MOTOR – HELICAL BEVEL GEAR MOTORS

MODULOG modular concept uses various mounting shafts to add options such as brakes, encoders, and external fans that can be field-retrofitted after installation

MODULOG modular concept uses various mounting shafts to add options such as brakes, encoders, and external fans that can be field-retrofitted after installation

SIMOLOC keyless tapered shaft locking system allows for easier installation on hollow shaft applications

Features

Aluminum housings – Lightweight and no paint required

Standard 9-pin terminal block – In 3×3 configuration

Conduit box – with NPT-tapped holes

Inverter-duty NEMA Premium® motors (230/460VAC, 60Hz)

Synthetic oil standard – For longer maintenance intervals

Gear teeth – Hardened and ground for infinite life

Solid, hollow, and SIMOLOCshaft types

Foot, flange, and torque arm mounting

Common Dimensions – Inch or metric shafts

SIEMENS GEAR MOTOR – WORM GEAR MOTORS

Worm geared motors are very silent and represent an economic solution especially for low power ranges. They achieve high gear ratios and can be also used in narrow spaces thanks to their compact design. Available with one or two stages and are being offered in foot or flange-mounting versions. SIMOGEAR worm geared motors boast with SIMOLOC – keyless tapered hollow shaft locking system. They are being offered with solid or hollow shafts.

Application of SIEMENS GEAR MOTOR – WORM GEAR MOTORS

Pumps and Fans

Hazardous Environments

Conveyor Systems

Specialized Machinery

Specification

Solid shaft, hollow shaft, and SIMOLOC keyless tapered shaft locking system

Foot, flange mounting

2 or 3-stage construction

NEMA Premium® motors

Energy efficient (Mechanical efficiencies up to 96%)

Integrates with Siemens drives and automation

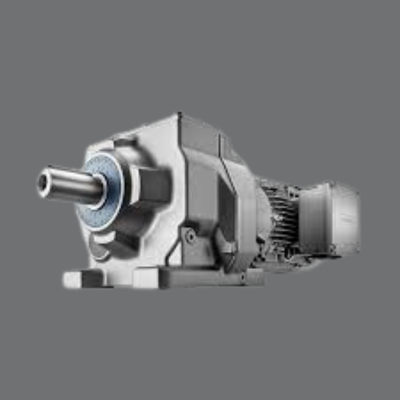

SIEMENS GEAR MOTOR – HELICAL GEAR MOTORS

Helical geared motors reach high gear ratios thanks to shank pinion. They provide very economic performance as well as they are high energy efficient (efficiencies 98% per stage). Available as well in high power range. They are offered with one, two or three stages in foot and flange-mounting version with solid shaft. SIMOGEAR helical geared motors among others find the application in conveyor belts, when transporting packaged goods and in vertical conveyors.

Applications of SIEMENS GEAR MOTOR – HELICAL GEAR MOTORS

Mixers and Agitators

Conveyor Systems

Specialized Machinery

Pump and Fan System

Specification

SIMOGEAR helical gear motors also reach high gear ratios due to shank pinion.

SIMOGEAR helical geared motors are available for the power range up to 20 Hp (15 kW) and rated gear unit torques up to 5,900 ft-lb (8,000 Nm).

Solutions utilizing helical geared motors are capable of an extremely variable speed range.

Solid shaft, hollow shaft, and SIMOLOC keyless tapered shaft locking system

Foot, flange mounting

2 or 3-stage construction

NEMA Premium® motors

Energy efficient (Mechanical efficiencies up to 96%)

Integrates with Siemens drives and automation

SIEMENS GEAR MOTOR – PARALLEL SHAFT GEAR MOTORS

Parallel shaft geared motors are also suitable to use in narrow construction spaces. They boast with high energy efficiency (efficiencies of 98% per stage). SIMOGEAR parallel shaft geared motors reach high gear ratios thanks to the plug-in pinion. Is it possible to place hollow shaft on both sides. They have two or three stages and are mounted with foot or flange-mounting, housing flange or shaft mounting with torque arm. They can be provided with solid shaft, hollow shaft, splined hollow shaft or hollow shaft with shrink disc. They are typically used for agitator drives, carriage drives, shelf access equipment and vertical conveyors.

Applications of SIEMENS GEAR MOTOR – PARALLEL SHAFT GEAR MOTORS

Agitator Drives

Shelf Access Equipment

Vertical Conveyors

Mixers and Extruders

Narrow Construction Spaces

Specialized Machinery

Specification

Very energy efficient (efficiencies of 98 % per stage)

Hollow shaft on both sides possible

High range of transmission ratios (plug-on pinion)

Solid shaft, hollow shaft, and SIMOLOC keyless tapered shaft locking system

Foot, flange (B5, B14), or torque arm mounting

2 or 3-stage construction

Choice of NEMA Energy Efficient or NEMA Premium® motors

Energy efficient (Mechanical efficiencies up to 96%)

Integrates with Siemens drives and automation

FAQ

Are Siemens gear motors compatible with automation systems?

Yes, Siemens gear motors can integrate seamlessly with Siemens automation systems, such as SIMATIC and SINAMICS, providing enhanced control and efficiency.

How do I select the right Siemens gear motor for my application?

To choose the right gear motor, consider:

- Torque and speed requirements

- Mounting configuration (foot, flange, or shaft-mounted)

- Environmental conditions (temperature, humidity, etc.)

- Application-specific demands

What maintenance is required for Siemens Parallel Shaft Gear Motors?

Regular inspections and adherence to the manufacturer’s guidelines are recommended. These motors are designed to be low-maintenance, but proper care will ensure long-term reliability.