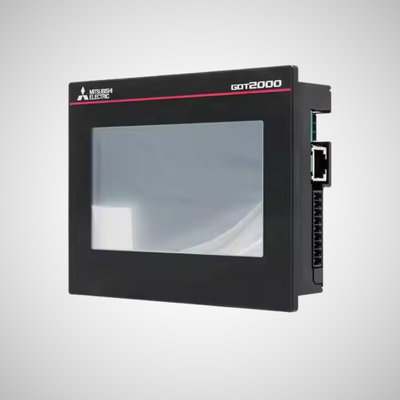

Human Machine Interface

Get information on HMI online in India

A Human-Machine Interface (HMI) is a user interface or dashboard that connects a person to a machine, system, or device. While this term can technically apply to any screen allowing user interaction, HMIs are most commonly used in industrial processes.

HMIs share similarities with Graphical User Interfaces (GUIs) but are not the same. GUIs are often integrated within HMIs for visualization. In industrial settings, HMIs can:

- Visually display data

- Track production time, trends, and tags

- Oversee KPIs

- Monitor machine inputs and outputs

Think of how you interact with your air-conditioning system to check and control the temperature in your home. Similarly, a plant-floor operator might use an HMI to control the temperature of an industrial water tank or see if a certain pump in the facility is running.

Who Uses HMI?

HMI technology is used by almost all industrial organizations and various other companies to interact with their machines and optimize processes.

The most common users of HMIs are operators, system integrators, and engineers, particularly control system engineers. These professionals rely on HMIs to monitor processes, diagnose problems, and visualize data.

Common Uses of HMI

Data Visualization: Displaying real-time data, trends, and metrics, making it easier for operators to monitor system performance.

Production Tracking: Monitoring production time, output, and efficiency to ensure processes are on track.

KPI Monitoring: Keeping track of Key Performance Indicators to maintain optimal performance and achieve business goals.

Machine Control: Allowing operators to control machinery, adjust settings, and manage operations directly through the interface.

Energy Management: Monitoring and managing energy consumption to improve efficiency and reduce costs.

Integration with SCADA, ERP, and MES Systems: Connecting with other systems to provide comprehensive oversight and control of industrial processes.